Category: Motor

Five days at McGregor Motorsport

5th July 2018

This week was one I was so looking forward to but obviously there were so many factors that could change and not obtain a very significant part of the build. The K24A motor was fully re-built more than five years ago and had simply sat in the corner waiting to actually do what it was intended to do…start!

I was really lucky to have Evan Morgan solve the engine loom problems with a plug from a Honda Jazz Loom that he connected to the K24A loom. This while I am writing seems such a simple task, but it took nearly eight hours. Evan was extremely confident in the loom, however we were not that confident in the car loom being about to match Evan’s work! Well it proved to be true as the car loom had a mind of its own and many hours of searching and testing still left doubts hanging over the Friday start.

Friday 10:00am Evan arrived, attached his laptop to the ECU and loaded a startup program. I would love to say it started immediately but with many head scratching options it finally came to life…what a week!

Back together

Monday 27th February, 2017

Once the welding was finished it was time to check all the components and begin to re-build the car. Scott has wisely decided after discussions about the build plan to assemble the entire car for testing to complete satisfaction before taking it all apart for painting, powder coating then assembly. I am still looking at door design and overall wet weather options…a nice project indeed.

Saturday 4 February, 2017

Fabrication

The final parts arrived from Speed Science and fitted so time to pull out the motor and gearbox.

Scott is really organized, parts are always clearly stored and not stuffed into boxes and dark places…

It was great to see the motor and gearbox out of the car which allows the belly pan to be fabricated.

3 December, 2016

Headers need a little thought from this 2014 “mock-up” by Mark

Saturday 3 December, 2016

K20A Parts arrive; Scott is already mocking them up and it’s looking really good.

Saturday 26 November, 2016

Some quick decisions needed to be made, the old question to “fabricate” or “bolt on”…this is a no-brainer as the quality of bolt-on parts just makes so much more sense. Gone are my days of crawling around junk yards and re-furbishing a twenty year old part. The Honda K2 Motor is certainly not new but the amount of bolt on new parts is incredible. New Zealand is really fortunate to have a total one stop online shop. Speed Science – Order Performance Car Parts Online, Stocked In NZ & Shipped To Your Door: Global Brands, World Class Service. Come Take A Look!

Some quick decisions needed to be made, the old question to “fabricate” or “bolt on”…this is a no-brainer as the quality of bolt-on parts just makes so much more sense. Gone are my days of crawling around junk yards and re-furbishing a twenty year old part. The Honda K2 Motor is certainly not new but the amount of bolt on new parts is incredible. New Zealand is really fortunate to have a total one stop online shop. Speed Science – Order Performance Car Parts Online, Stocked In NZ & Shipped To Your Door: Global Brands, World Class Service. Come Take A Look!

https://www.speedscience.co.nz

Shopping time….

Skunk2 Ultra Street Intake Manifold

S90 74MM THROTTLE BODY

BLACKWORKS RACING BILLET FUEL RAIL

GRAMS PERFORMANCE (AKA SKUNK2) 550CC INJECTORS

K-TUNED COOLANT HOUSING WITH -12 AND FILLER

K-TUNED HALL EFFECT TPS

SKUNK2 MAP SENSOR

Tuesday 20 September, 2016

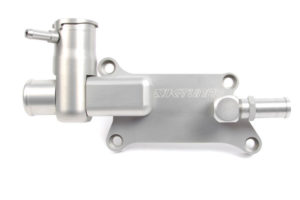

THE K-TUNED WATER PUMP BLOCK OFF PLATE SYSTEM

Scott has just sent photos of the The K-Tuned Water Pump Block Off Plate system designed to setup a K-series engine to use an electric water pump cooling system. It replaces all of the bulky and heavy OEM accessories with a simple lightweight aluminum plate. The first part is now on the engine block and looking great….

Sunday 4 September, 2016

THE K-TUNED WATER PUMP BLOCK OFF PLATE SYSTEM

Applications: All K-series engines Except K24Z-Series

Back in 2006 we originally designed our K-Series Water Plate Kit that ran D/B Series alternator. We have revisited the project to breathe some new life into it. We constantly strive to improve and bring the very best to our customers and racers. The original design is still for sale today and that will not change. However, we have brought some nice new options with the ability to run a k-series alternator. The new kit can be installed on your original K-Tuned Water Plate including original designs for those who want to upgrade to a k-series alternator.

For several years now racers have used electric water pumps to reduce the power robbing effects of parasitic drag from their engines. The reason is pretty simple; by reducing the number of accessories the crank needs to turn there can be some noticeable and impressive gains. The K-Tuned Water Pump Block Off Plate system was designed to setup a K-series engine to use an electric water pump cooling system. It replaces all of the bulky and heavy OEM accessories with a simple lightweight aluminum plate. The original alt bracket setup was designed to hold the older and lighter B or D series alternator and works well. The only difference is a little extra work for installation, so we decided to design a compatible alternator bracket setup that works with the original OEM K-Series alternator.